From “frozen glider clicking” to measurement by a computer tomograph to 5-day stress: HINNO Clic gliders undergo many an “endurance test” in quality testing – even unconventional ones!

Genuine Swiss precision work leaves nothing to chance. This is why HINNO takes every precaution before, during and after production to ensure that Clic gliders live up to their excellent reputation worldwide. This is why the bar is also set much higher than usual in the quality inspection. Quality from Switzerland obliges!

High-precision production in Switzerland

An original Clic curtain glider has to be able to do a lot: glide smoothly, carry a load of up to eleven kilos, be UV-resistant and remain fully functional in the long term – even after years of washing or dry-cleaning. First-class materials and sophisticated, high-precision workmanship in Switzerland lay the foundation for this. Extensive quality testing does its part to ensure that only flawless curtain gliders are sold.

Test series during production

During ongoing production, the HINNO quality managers remove sliders at close intervals in order to subject them to visual inspections, part measurements using a computer tomograph and push-pull tests with result logs, as well as functional one-click checks. If only one glider fails one of these tests, production is halted until the fault has been clarified.

Tests 20 days after production

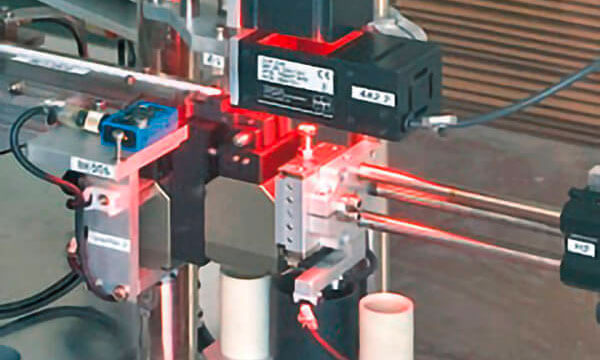

After an initial storage phase, further quality checks are carried out. These tests cover all the practical requirements of gliders: from various load and click-in tests to measuring the wing tension using a pressure sensor.

The most unconventional method is the “deep-freeze click”: Here, frozen gliders are clicked several times into a curtain track to test whether the wings of the Clic gliders do not break or lose flexibility even under extreme conditions.

All these checks ultimately have one goal: HINNO wants to ensure that only faultless Clic gliders are delivered to the customer – and that they retain their functionality for many years if used properly.

HINNO quality assurance at a glance:

During production

- Visual inspection

- Parts measurement via a

Computer tomographs - Push-pull tests

- Manual click-in

20 days after production

- One-click tests of frozen sliders

- Tensile load with tips of 11 kg per slider

- 5-day continuous load with 5 kg per slider

- One-click test by machine with measurement of sash tension by pressure sensor

- Visual inspection with camera

Certified according to ISO 9001 and ISO 14001

ISO 9001: Download PDF

ISO 14001: Download PDF

- Read here why Clic curtain gliders must have “Ironman qualities” when used in the automotive industry